Metal Castings and their critical importance in today’s global industries

Wiki Article

Comprehending the Steel Castings Process: A Comprehensive Guide for Beginners

The Metal Casting process is a fundamental strategy in making that changes molten metal right into strong types. Newbies should grasp the different techniques included, such as sand spreading and pass away casting. Understanding the products, design principles, and precaution is similarly crucial. Each facet plays a critical role in attaining successful results. As one navigates these complexities, the inquiry of how to enhance each action for improved outcomes comes to be progressively relevant.The Fundamentals of Steel Casting

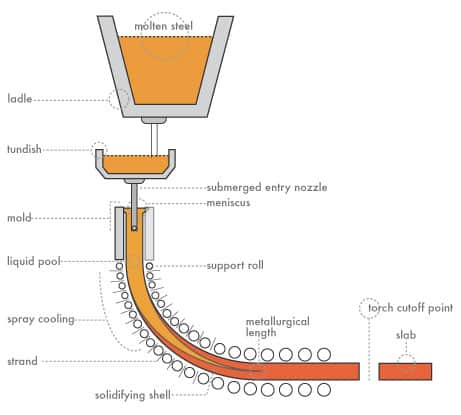

Metal Casting has evolved over centuries, its basic principles continue to be essential and regular to the production procedure. At its core, Metal Casting involves the change of liquified steel into strong objects via various methods. The procedure begins with the development of a mold and mildew, which specifies the form of the final product. When the mold is prepared, metal is heated up to its melting point and put right into the tooth cavity. After cooling down, the steel strengthens, taking the form of the mold and mildew.There are a number of casting approaches, including sand spreading, financial investment casting, and die casting, each with special benefits and applications. The choice of method depends on elements such as manufacturing quantity, material kind, and preferred precision. As soon as cast, the end product might undertake added processes like machining or surface treatment to attain the required surface and requirements. Comprehending these basics is vital for anyone interested in the field of Metal Casting.

Understanding Products Used in Metal Casting

Materials play an important role in the Metal Casting procedure, influencing the end product's residential properties and performance. Numerous metals are made use of, consisting of aluminum, bronze, iron, and steel, each offering distinct features matched for particular applications. Aluminum is lightweight and corrosion-resistant, making it optimal for vehicle components. Iron, especially cast iron, is favored for its excellent wear resistance and durability. Steel provides high strength and flexibility, typically used in hefty machinery components. Bronze, understood for its rust resistance and machinability, is frequently employed in marine applications.Along with the steels, various casting materials, such as sand, plaster, and ceramic, are used to create mold and mildews. Sand spreading, one of the most common technique, utilizes silica sand because of its thermal security and ability to develop detailed forms. Plaster and ceramic molds supply better details yet may require even more intricate procedures. The choice of products straight impacts the efficiency, expense, and high quality of the casting operation.

The Style Refine: From Concept to Plan

The style procedure in Metal Casting begins with the first principle growth, where ideas are generated and evaluated. This is complied with by the application of CAD modeling strategies, permitting exact visualizations of the layout. Lastly, the blueprint completion actions guarantee that all specifications are precisely documented for production.Initial Principle Growth

First idea growth notes an important phase in the Metal Casting process, where concepts change into tangible styles. During this phase, developers collaborate with stakeholders and engineers to brainstorm and fine-tune preliminary principles. They think about variables such as capability, aesthetic appeals, and manufacturability, making certain that the design meets the required requirements and performance criteria. Illustrations and harsh drafts are developed to picture the ideas, enabling for preliminary analyses of usefulness and cost-effectiveness. This stage likewise includes determining materials and possible spreading methods that align with the layout objectives. Eventually, first principle advancement prepares for a thorough blueprint, directing the subsequent stages of the spreading process and guaranteeing an effective change from concept to reality.CAD Modeling Techniques

Transforming ideas right into specific layouts, CAD modeling techniques play a pivotal role in the Metal Casting process. These methods make use of innovative software application to create detailed three-dimensional models that precisely mirror the intended product. By employing tools such as parametric modeling, strong modeling, and surface modeling, designers can manipulate dimensions and shapes with simplicity. CAD systems additionally promote simulation and evaluation, enabling the recognition of possible flaws before production starts. This positive technique decreases material waste and maximizes the layout for manufacturability. Additionally, CAD designs can be conveniently customized, allowing quick models based upon comments. Fundamentally, CAD modeling works as the foundation of the design process, linking the gap between initial principles and the ultimate production-ready styles.Plan Finalization Steps

Adhering to the production of detailed CAD versions, the next phase includes blueprint completion, which is vital in equating digital layouts right into workable prepare for production. This process begins with examining the CAD designs for accuracy and conformity with specifications. Once validated, the dimensions, tolerances, and product specifications are carefully detailed to guarantee clarity. Incorporating notes and notes aids communicate crucial info pertaining to casting procedures, surface area finishes, and assembly requirements. The completed blueprint undergoes a strenuous approval procedure, usually involving collaboration with designers and production teams to attend to any type of prospective concerns. Revisions are made and approvals acquired, the blueprint is officially launched, offering as the fundamental document for the succeeding phases of Metal Casting, consisting of pattern making and mold and mildew layout.The Metal Casting Techniques Discussed

Metal Casting methods include a variety of methods used to form liquified steel into preferred kinds. These strategies vary according to the type of product, intricacy of the layout, and manufacturing volume. Sand casting is among the most common approaches, entailing the creation of a mold and mildew from sand to hold the molten steel. Investment casting, or lost-wax spreading, permits elaborate styles by utilizing a wax pattern that is disappeared. Pass away casting utilizes high-pressure injection of liquified steel right into a mold, ideal for mass production. Other techniques consist of permanent mold and mildew casting, which makes use of reusable molds, and centrifugal spreading, where rotational pressures aid in loading the mold and mildew. Each technique has its benefits and applications, making it vital for makers to pick the ideal method based on their certain needs and demands. Understanding these methods is important for any person associated with the Metal Casting procedure.

Completing Processes: Enhancing Your Casted Product

Completing procedures play a necessary function in boosting the quality and appearance of casted items. Numerous surface area treatment methods, such as sprucing up and layer, are utilized to boost longevity and appearances. Additionally, quality examination approaches ensure that the end product meets specified criteria and performance needs.

Surface Therapy Techniques

A variety of surface area therapy methods play an important function in enhancing the high quality and durability of casted items. These strategies consist of approaches such as shot blasting, brightening, and coating. Shot blasting effectively gets rid of surface flaws, enhancing the practical and visual qualities of the spreading. Sprucing up provides a smooth coating, which is especially essential for ornamental applications and parts calling for marginal rubbing. Finishing strategies, such as electroplating or powder finish, offer additional protection versus deterioration and wear, guaranteeing longevity. Surface area treatments can boost attachment for succeeding procedures, such as paint or bonding. By employing these techniques, producers can attain remarkable surface area quality, which is vital for the efficiency and life expectancy of Metal Casting in numerous applications.High Quality Inspection Techniques

Effective top quality evaluation approaches are necessary for ensuring the integrity and efficiency of casted items after the finishing processes. Different methods are utilized to evaluate the high quality of Metal Casting, consisting of aesthetic evaluation, dimensional checks, and non-destructive testing (NDT) Visual inspection permits for the identification of surface defects, while dimensional checks ensure that products fulfill specified resistances. NDT methods, such as ultrasonic testing and radiographic assessment, offer much deeper insights right into inner stability without damaging the castings. Additionally, mechanical screening, such as tensile and solidity tests, assesses product buildings - Wisconsin Aluminum Foundry. By using a combination of these techniques, makers can boost product top quality and integrity, ultimately leading to greater consumer fulfillment and decreased manufacturing expensesSecurity Considerations in Metal Casting

While the Metal Casting process offers numerous benefits, it likewise offers a variety of safety and security threats that must be meticulously taken care of. Workers in casting centers are revealed to high temperature levels, molten steels, and harmful materials, which can bring about serious injuries if proper safety measures are not taken. Individual safety tools (PPE) such as heat-resistant handwear covers, deal with guards, and protective garments is vital to decrease risks.Furthermore, the existence of fumes and dirt requires proper ventilation systems to guarantee air quality - Aluminum Castings. Normal training on safety and security procedures is important for all staff members to identify possible threats and react properly. Emergency treatments ought to be established, consisting of fire safety and security steps and emergency treatment schedule. Maintenance of equipment and proper handling of products better contribute to a safer working setting. By prioritizing these safety factors to consider, Metal Casting procedures can protect their labor force and maintain reliable production procedures

Often Asked Concerns

What Are the Ecological Effects of Metal Casting?

Metal Casting can result in ecological effects such as air and water pollution, source exhaustion, and power intake. In addition, inappropriate waste monitoring and discharges from factories contribute to ecological disruptions and wellness dangers for neighboring communities.How Do I Select the Right Steel for Casting?

To pick the right steel for spreading, one should think about elements such as mechanical homes, corrosion resistance, thermal conductivity, and price. Assessing the intended application and ecological problems is crucial for ideal choice.What Are the Common Flaws in Metal Casting?

Common defects in Metal Casting include porosity, shrinking, sand inclusion, and misruns. These problems usually arise from incorrect material option, poor style, or problems in the casting procedure, impacting the end product's top quality and performance.

How Can I Enhance My Steel Casting Skills?

To improve Metal Casting skills, one must exercise continually, research study spreading strategies, analyze previous projects for defects, look for responses from knowledgeable casters, and continually trying out different materials and techniques to improve efficiency and understanding.What Is the Cost of Beginning a Steel Spreading Service?

Beginning a metal casting company normally requires a first financial investment of $5,000 to $50,000, relying on equipment, materials, and center costs. Aspects like place and scale can substantially Metal Castings affect total start-up costs.The Metal Casting process is a fundamental strategy in manufacturing that changes molten steel into solid forms. Novices need to grasp the various methods involved, such as sand casting and die casting. There are numerous casting methods, consisting of sand casting, financial investment spreading, and die casting, each with unique benefits and applications. Investment spreading, or lost-wax spreading, permits for detailed styles by using a wax pattern that is melted away. Various other methods include permanent mold casting, which uses reusable mold and mildews, and centrifugal casting, where rotational pressures aid in filling up the mold.

Report this wiki page